-

with the sale of their memphis factory, anyone know? Will they be subcontracting?

And i'll just say this in advance...Please no politics...

-

10-26-2017 11:57 AM

-

I think they'll downsize and stay in the states. I don't think it's political to say they know there's "cache" in "Made in the U.S.A."

-

They say they are looking for a smaller facility in Memphis, but I think they will just downsize to two locations, Nashville and Bozeman and see how that works. Keeping three plants going in the face of declining sales must be expensive.

OTOH, if this CME blowout continues and is profitable, maybe they will find a smaller, cheaper Memphis location to keep things going.

-

someone told me that they are going to locally outsource some of their manufacturing

Originally Posted by Stringswinger

Originally Posted by Stringswinger

-

I hope they move just east of Memphis to maybe Oakland or Arlington, TN

Then it will be near my parents and I can visit it without a long drive to downtown Memphis when I'm back home for the holidays

-

terada factory japan

worked for gretsch!

cheers

-

I hope these financial problems at least has a silver lining. Maybe this will help Heritage.

-

Fender has hired individual luthiers to make Custom shop Strats and Teles in the past. I could see Gibson hiring small guitar makers to make their guitars. Or perhaps hire a small pickup maker to make their pickups?

Originally Posted by jzucker

Originally Posted by jzucker

But I do not expect to see the Gibson brand on guitars made outside of the States. Gibson has been protective of the brand. But if NAFTA is kept in place, some production in Mexico is a real possibility. Martin has been producing some low end guitars there and Fender probably sells more Mexican made Fenders than they do American made ones.

-

That would be a nice option if they don't stay in the States.

Originally Posted by neatomic

Originally Posted by neatomic

-

Probably for the high end archtops they will do like D'Angelico did for the New Yorker's a year or so ago and hire a luthier to spend a year making a run of guitars. Give that luthier all the internal doc's to work from and go. D'Angelico hired Victor Baker and VB stopped production on his own guitars during the the duration of the contract.

I would guess for the basic ES guitars those will be in batches that a select few in Japan or Korea get to bid on. They know who to use since it will probably be same ones making Epiphone, just now will be a higher quality version. The ES series guitars are more labor intensive so they are doing what manufactures of everything else are doing.

-

One thought but I think unlikely is they could of come up with a more CNC oriented way to make semi-hollow and low end archtops. So this is about retooling and moving to smaller factory. Some of the luthiers have been experimenting a lot over past few years with semi that most of the work is done by CNC. CNC saves a lot of money and brings more consistency, also easier to make variations of different models like vintage this, and custom run of that. So could be a move to new generation ES guitars.

-

Originally Posted by docbop

Originally Posted by docbop

I toured the Memphis plant last year ... and they make the ES manufacturing look almost simple ... I'm sure it isn't, but they have it pretty well laid out

I'm no cnc expert so maybe I just didn't know what I was looking at,

but it seemed to me there were surprisingly few cnc machines involved in the ES construction ... certainly cnc to shape necks, but it didn't seem like much else

lots of pressing the pieces together and waiting on the glue to dry ... the top and back start out as a square laminate that's pressed into the desired archtop shape 175, 335, 275, etc. ... then cut out the body outline ... maybe the machine that cuts the outline of the body shape was cnc

similar situation with the sides, with the steam press to bend them to shape

glue back, sides and top together and wait for glue to dry ... trim the edges ... add binding ... add neck .. then off to the spray booth

and each process can be done quickly with the machines and tools they have ... except for waiting on the glue and lacquer to dry ...

It was quite fascinating

In the end most of the work is in the sanding and finishing

-

Just one luthiers experience, but I don’t know that CNC will bring too much to the manufacture of laminate hollow body guitars.

I make guitars and have a CNC machine. It is very useful making tools and jigs. But as was said earlier, it is a lot of pressing veneers, glueing them up in jigs, and applying finish. Very little of it gets done with a router bit or endmill.

Sent from my iPhone using Tapatalk

-

Originally Posted by Bluedawg

Originally Posted by Bluedawg

and FWIW I expect that they will consolidate all domestic production -- all three guitar factories -- in one domestic location. Nashville makes a lot of sense.

-

Originally Posted by Sam Sherry

Originally Posted by Sam Sherry

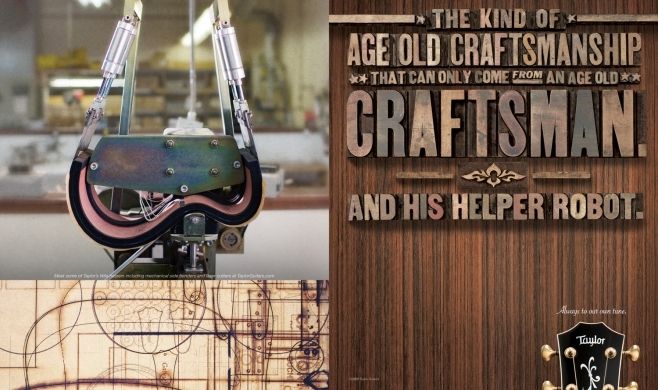

I've done the Taylor tour, too ... back in 2005 IIRC

A very cool factory to visit

-

There are some folks in Kalamazoo, MI that might be able to help them out...

-

If their facilities in Boseman and Nashville are successful, there's no reason for them to consolidate. If they wanted to do that they could use the large plant in Memphis they currently have.

They say they want to downsize in Memphis, OK, but as I've said I'll believe it when I see it.

I think it would make sense for them to outsource some models to other countries--335, LP, etc. and just have a Custom series made in the States. (Which, come to think of it, is more or less what the Epiphone division is for.) That's what I would do if I were in their position.

Still waiting on them to ask my advice...

-

gibson already has a relationship with terada via their orville line (90's)

epi elite series were made there too!

a 1992 orville

cheers

-

Dare I say that if they made guitars in Terada their quality control would be greatly improved.... at least for the low-mid range guitars. I'm yet to see a Gibson as well finished as my Terada made Gretsch.

-

that was my point for- "it worked for gretsch" comment ^

Originally Posted by entresz

Originally Posted by entresz

purely from a quality control standpoint, many old time gretsch players prefer the qc of the current terada gretsch pro line to the sacred old williamsburgh brooklyn factory models...mojo aside

cheers

ps- not to say one of those special olde brooklyn mades couldn't beat anything that ever came out of terada...but...Last edited by neatomic; 10-26-2017 at 09:06 PM. Reason: ps-

-

From what I have read Gibson plans on keeping there ES line in Memphis just at a much smaller facility with no more factory tours of the new plant. The 1990's were the golden years for the Memphis ES line. Hopefully they can get back to that QC level.

This may very well turn out to be a win/win.

Harley almost went belly up when owned by AMF. Now they are producing some of the best made motorcycles in the world.

A complete restructure is just sometimes necessary to get back on track. Your iconic name can only carry you for so long.

-

Originally Posted by vinnyv1k

Originally Posted by vinnyv1k

I read the same article and don't believe it, if they were staying they'd remain open until new facility is ready then forklift what machinery they are keeping, transfer the people they are keeping and then close the old doors. That way you keep money coming in and don't have to warehouse machinery and lose people. Gibson needs cash as well as reduce COGs I say right now they are saying what they need to, to keep customer happily in the dark.

-

Let's all remember that Gibson opened the Nashville plant to cut costs way back when. Michigan was a Union State, Tennessee is not. At the time, Gibson was facing pressure to cut costs to compete with Japan. Now Gibson is fighting a battle on two fronts, compete with China and face a declining interest in it's core product, namely guitars.

Smart move from my perspective is downsize till profitability returns. We are all guessing at this point and the reality is that Gibson may not even be sure of what it is going to do at this point.

We all need to hurry up and wait to find out....

-

SS, This could not have been better said. Continue on, don't over produce and by all means, Maintain the exclusivity of the brand.

Originally Posted by Stringswinger

Originally Posted by Stringswinger

If you really think about it, Gibson is one of the top 10 national treasure "brands" we have here in the US. They already have Epiphone to rake in some bucks on commodity instruments. Gibson should only be synonymous with hand made, elite level guitars. Not mass produced great guitars.

JD

-

I thought I read somewhere that when Gibson sells the property, they will have a clause that will allow them to stay in the factory for a certain amount of time before they move into a smaller space.

Reply With Quote

Reply With Quote

$8500 - 2010 Moffa Maestro Virtuoso Archtop Black...

Today, 03:35 AM in For Sale